Why the sliding bearing of melt pump fails?

The failure of the sliding bearing of the melt pump is mainly caused by two reasons: abrasive wear and adhesive wear. In the actual use process, when the outlet pressure of the melt pump is higher, the shear force of the shaft on the lubricating film is greater, the damage of the lubricating film will be more serious, and the bearing area will be closer to the mixed friction, even sometimes in the dry friction state, the damage to the drive shaft and bearing surface will be more severe.

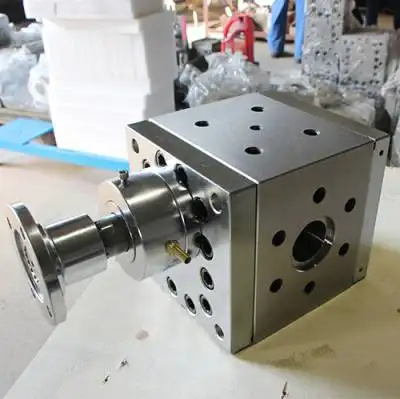

The service life of the melt pump mainly depends on whether a good load-bearing lubricating film can always be maintained between the sliding bearing and the journal. The outlet pressure of the melt gear pump, the rotational speed of the melt pump, and the viscosity of the conveyed melt all directly affect the load-bearing capacity of the lubricating film; In actual production, the installation, overhaul, operation and maintenance of the melt pump should fully consider the influence of the above factors, so that the sliding bearing and journal surface are always in a good lubrication state, reduce the wear of the journal and bearing, and extend the service life of the melt pump. The special melt pumps provided by Zhengzhou Batte melt pump manufacturer include melt pump of melt blown cloth extruder, rubber melt transfer pump, reactor melt discharge pump, etc. You are welcome to inquire. info@battemachinery.com

pre:Application of melt pump in polymer processing

next:Melt pumps in the XPS extruded foam sheet industry